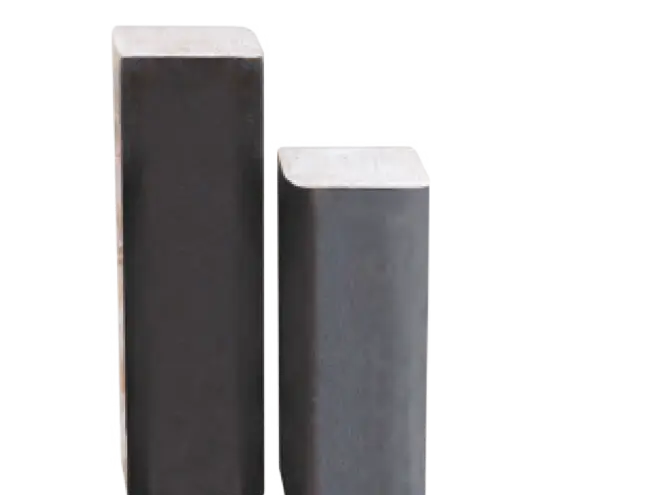

Round Cornered Squares

Quality Craftsmanship:

Our Hot Rolled Round Cornered Squares (RCS) are meticulously crafted to ensure freedom from surface defects or cracks. The products exhibit a consistently uniform internal structure, a crucial characteristic for the production of drop-forged components, particularly in the automotive industry.

Radius Edge for Safety and Standards:

Incorporating a radius edge serves a dual purpose. It enhances safety by eliminating sharp edges, and it aligns seamlessly with the stringent standards required by forging companies. This makes our hot-rolled RCS an ideal choice in the creation of flanges and fittings.

Supply Conditions:

● Size Range:

○ 63 RCS

○ 75 RCS

○ 95 RCS

○ 100 RCS

● Length:

○ Up to 8 meters

● Surface:

○ Hot Rolled (Black), ensuring a robust and durable finish.

● Quality Assurance:

○ 100% Ultrasonically Tested for integrity and reliability.

○ Spot Ground or Fully Ground to meet specific requirements.

○ Free of Surface Defects and Cracks, ensuring a flawless appearance.

○ Cold-swappable, providing versatility in applications.

○ Smooth Ends Without Sharp Edges, enhancing safety in handling.

Applications:

● Our Hot Rolled RCS finds its application in hot forgings, including both open-die and close-die forgings.

● Its versatility makes it a preferred choice across various industries.

Grade Verification Assurance:

● PMI Testing:

○ We employ PMI testing using handheld spectrometers to verify the grade.

● Radiological Purity:

○ Our products are guaranteed to be free from radioactive elements.

● Contamination-Free:

○ Rigorous checks ensure no contamination from Mercury and Lead, meeting the highest standards of purity and safety.

At the forefront of stainless steel hot-rolled bar manufacturing in India, we exceed industry standards, delivering products that embody quality, reliability, and a commitment to safety.