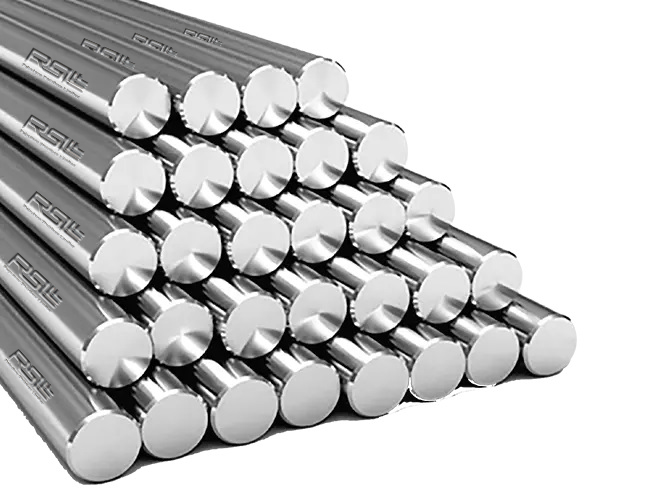

Round Bright Bars

Round bright bars by Rajputana Stainless Limited are the result of a meticulous cold working process, employing high-quality bright bar steel. This process includes cooling the bars and subjecting them to fine-finishing procedures like peeling, turning, grinding, and polishing, all executed at room temperature. The commitment to excellence is reflected in the methods of Rolling, Drawing, and Heat Treatment, ensuring superior quality.

Applications:

Renowned for exceptional weldability and machinability, our bright bars are ideal for precision machining components and the construction of robust structures. They play a crucial role in the engineering and construction sectors, providing prompt stability, strength, and durability to monumental structures.

Manufacturing Excellence:

As a premier bright bar supplier and stainless steel bright bar manufacturer in India, Rajputana Stainless Limited upholds a stellar reputation. Our global recognition is a testament to an unwavering commitment to quality and precision, making us a leader in the industry.

Supply Conditions:

● Size Range:

○ From 5 mm to 105 mm, ensuring versatility for various applications.

● Length:

○ Up to 8 meters, providing flexibility for diverse construction needs.

● Cold Drawn:

○ Centreless Ground: For precision and consistent diameter.

○ Peeled and Polished: Enhancing surface quality for a polished appearance.

○ Rough Peeled: Ideal for applications not requiring a smooth surface finish.

○ Smooth Turned Bars: Offering a smooth and uniform appearance

● Tolerances:

○ Meeting industry standards including h7, h8, h9, h10, h11, k12, and k13, ensuring precise dimensions as per requirements.

● Surface Finish:

○ Achieving a Roughness Average (Ra) of up to 0.2 mm (8.7 RMS), ensuring a high-quality surface.

● Straightness:

○ Maintaining straightness within 0.5 mm per meter, ensuring uniformity in shape.

● Grit Polish:

○ Offering K240, K320, or customization based on customer requirements, catering to specific finish preferences.

● Heat Treatment:

Options include:

○ Soft Annealing: Enhancing machinability and reducing hardness.

○ Solution Annealing: Optimizing material properties for specific applications.

○ Oil & Water Quenching: Tailoring hardness as per project requirements.

○ Tempering & Aging: Achieving desired strength and durability characteristics.

● Bars End Finish:

○ Providing flexibility in end finishes, including chamfered ends at 30°, 45°, 60°, as well as plain ends without burrs on sharp edges, catering to diverse construction needs.

● Specifications:

○ Meeting international standards such as EN, DIN, JIS, ASTM, BS, ASME, GOST, AISI/Nace MRO175, MR0103, ensuring compliance with global quality benchmarks.

● Quality Assurance:

○ Grade Verification: Through PMI testing using handheld spectrometers

○ Contamination-Free: Products are free from radioactive elements, Mercury, and Lead.

Rajputana Stainless Limited ensures that its bright bars not only meet but exceed industry expectations, providing a comprehensive range of supply conditions to cater to the diverse needs of its clientele.