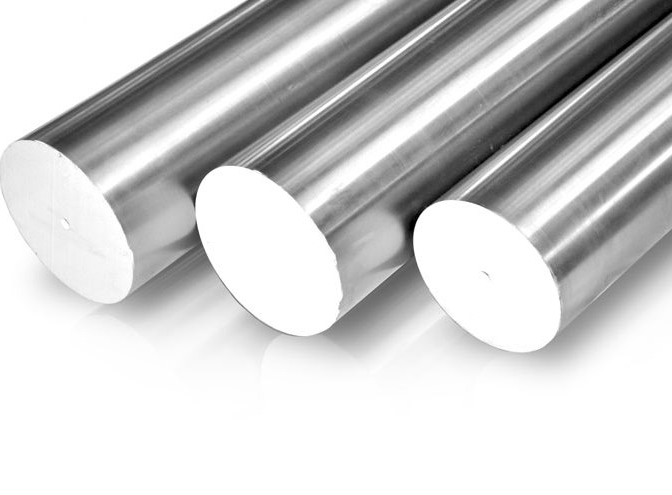

Forged & Proof Machined Bars

As a premier manufacturer of forged and proof-machined bars in India, Rajputana Stainless Limited stands out for its expertise in producing high-quality hot forged bars utilizing localized compressive forces. This intricate process involves precise hammer blows, often administered through a power hammer or die, to shape the steel into the desired form. To enhance malleability, the metal is meticulously heated in a furnace during the forging process. Although forged bars may entail a higher cost compared to rolled products, their unmatched physical properties make them exceptionally valuable, particularly for larger sizes.

Supply Conditions:

● Size Range: From 170 mm to 550 mm

● Length: Up to 6 meters, providing versatility for various applications.

● Tolerance: The manufacturing process ensures that the bars conform to strict standards such as ASTM A484 and EN10060, ensuring precision and reliability.

● Heat Treatment:

○ Soft Annealed: This heat treatment option involves heating the bars to a relatively low temperature, enhancing their machinability and reducing hardness.

○ Solution Annealed: The steel is heated to a high temperature, followed by a rapid cooling process, improving corrosion resistance and mechanical properties.

○ Normalizing: The bars are uniformly heated and then allowed to cool in ambient air, refining the grain structure for improved mechanical properties.

○ Quenched & Tempered: The bars are heated and then rapidly cooled (quenched) and subsequently tempered to achieve a balance of hardness and toughness.

● Quality Assurance Measures:

○ Rigorous Ultrasonic Testing: The bars undergo thorough ultrasonic testing to ensure their integrity and detect any internal flaws.

○ Exemption from Surface Defects and Cracks: The manufacturing process is designed to produce bars free from surface defects and cracks, ensuring structural reliability.

○ Grade Verification through PMI Testing: Portable spectrometers are used for Positive Material Identification (PMI) testing, ensuring the bars meet the specified grade.

○ Devoid of Radioactive Elements, Mercury, and Lead Contamination: Stringent measures are in place to ensure that the bars are free from harmful elements, meeting high safety standards.

At Rajputana Stainless Limited, our commitment to excellence is evident in the meticulous manufacturing processes and stringent quality control measures applied to our forged bars. We pride ourselves on delivering products that not only meet but exceed industry standards, providing our clients with the assurance of superior performance and durability.